In 2018, following the release of the first PLASMA Pedal - we were receiving the following type of comment on a regular basis - Wow, guys - I wonder what crazy sh** you will come up with next…

Our mojo was flowing, we were on the hunt for new ideas for creating and manipulating sound, for new ways of combining musical and engineering concepts in order to create a unique musical experience.

One day our head engineer Martins showed up at the office and said he'd had a weird dream about Motors… This statement instantly sparked a long brainstorming session and the matter was settled - we're gonna build something that makes Music with MOTORS.

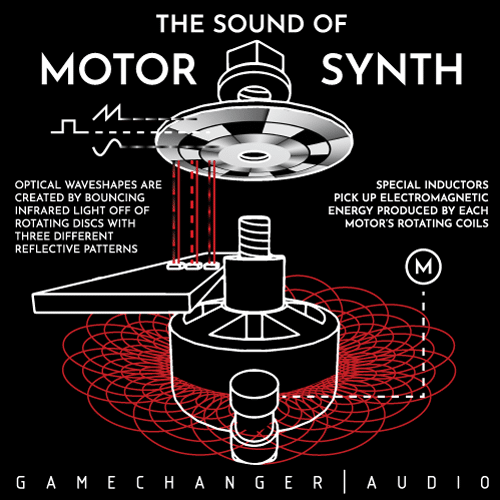

We started conducting the first series of experiments - placing electromagnetic pickups on various motor types and amplifying the signal, thus producing a variety of gorgeous and nasty drones, resonant noises and screeching tones.

It was clear that the crucial element to creating any Motor-based musical instrument would be an efficient and reliable MOTOR Driver system that could control the MOTOR'S rotation speed (RPM) in real-time with musical precision.

Realizing the challenge ahead, the engineering team recruits Valters, an engineer with a unique set of electromotor related skills and years of experience in this specialized area.

Valters joins the GCA Team and immediately begins work on a proprietary MOTOR Driver microcontroller system that uses Infra-red Optical discs (instead of a Hall-Sensor) in order to precisely measure and control the MOTOR's rotation speed. The first results are promising and we are able to play a Brushless DC MOTOR test-board via MIDI with decent precision.

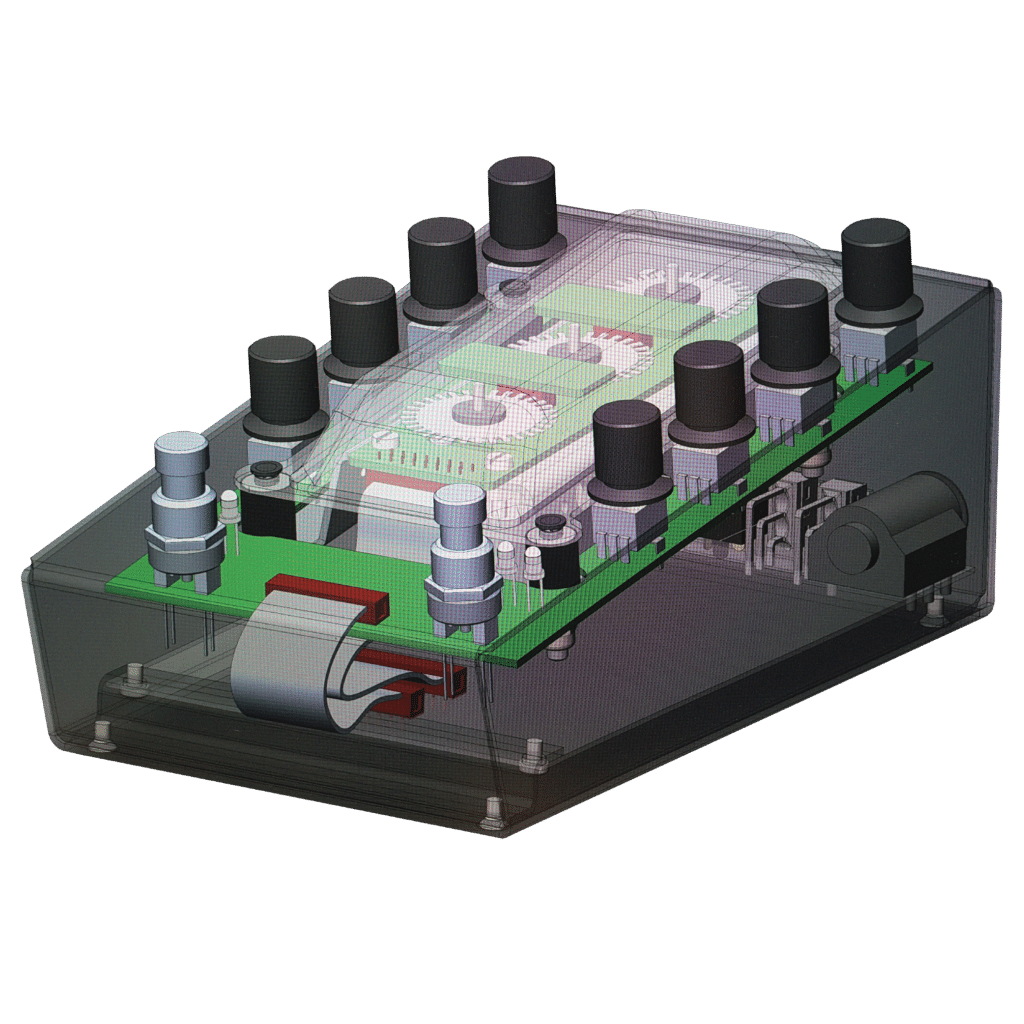

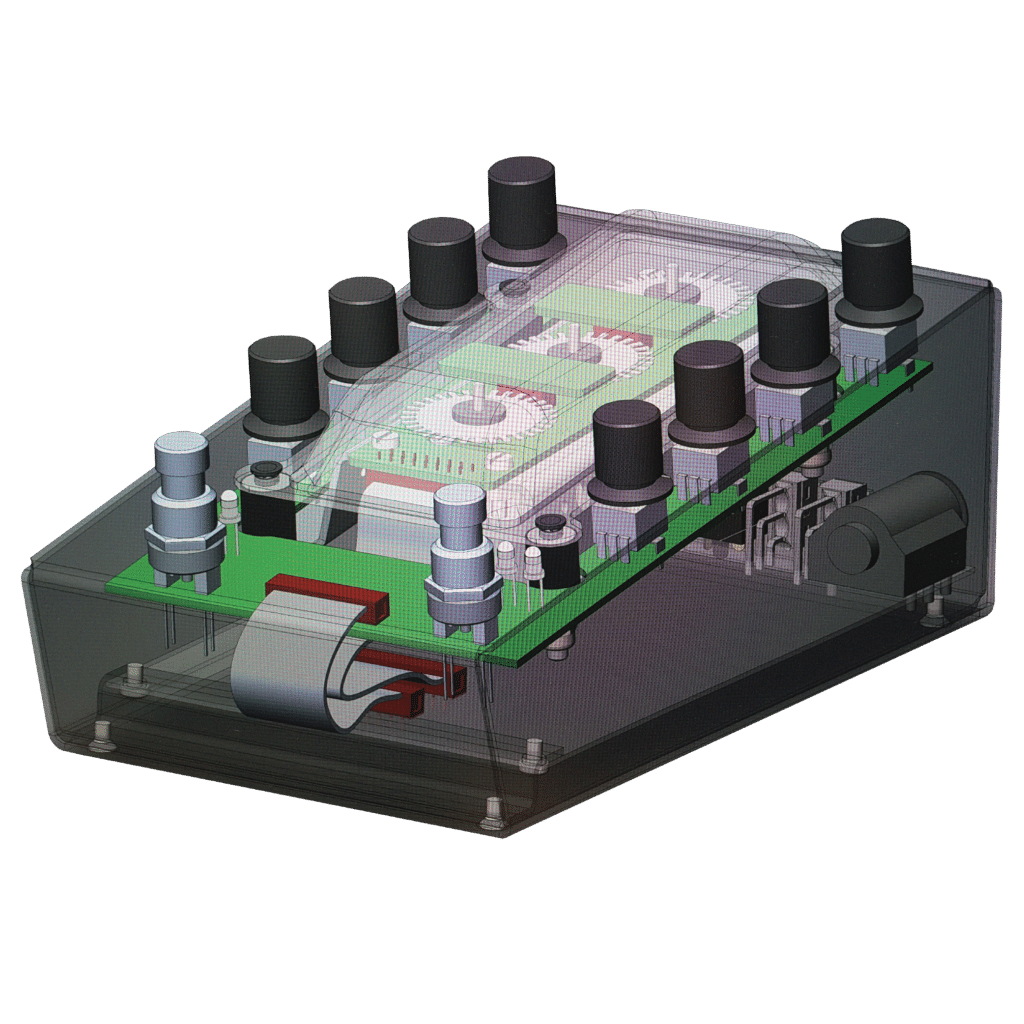

Valters’ successful Motor Driver experiments set off the green light for the rest of the team to start working on product design.Two totally different, but equally ambitious concepts are created - the MOTOR Piano and the MOTOR Pedal.

The MOTOR Pedal was designed to incorporate the sounds of brushed electromotors into the world of electric and bass guitar.

The three-motor voice block was capable of tracking a mono input signal and producing a pitched growling motor sound thanks to a specially designed electromagnetic inductor system. The Motors also featured an optical sine wave generator (disc) and controls for Acceleration, Amp Envelope, Blend, Tone, as well as two special FX modes - simple Arpeggiator and Octaver.

The MOTOR Piano is a new type of electromechanical musical instrument.

It is based on a 36 electromotor voice-block (brushless) equipped with specially designed “optical disks” for generating different waveforms. It offers 12-note polyphony with 3 voices (Motors) per musical note, a full-size keyboard with aftertouch, and loads of classic analog synth features including a Low Frequency Stepper Motor that acted as a mechanical LFO.

With only four months to go til' the 2019 NAMM show, the whole team works day and night to turn these crazy instrument designs into working prototypes.

The previous years' success of PLUS and PLASMA had set the bar high, and we'd already managed to gain a loyal fan-base that was expecting a new release each year.

However, as the deadline approached it was becoming increasingly clear that we wouldn’t be able to produce finished prototypes in time for the show.

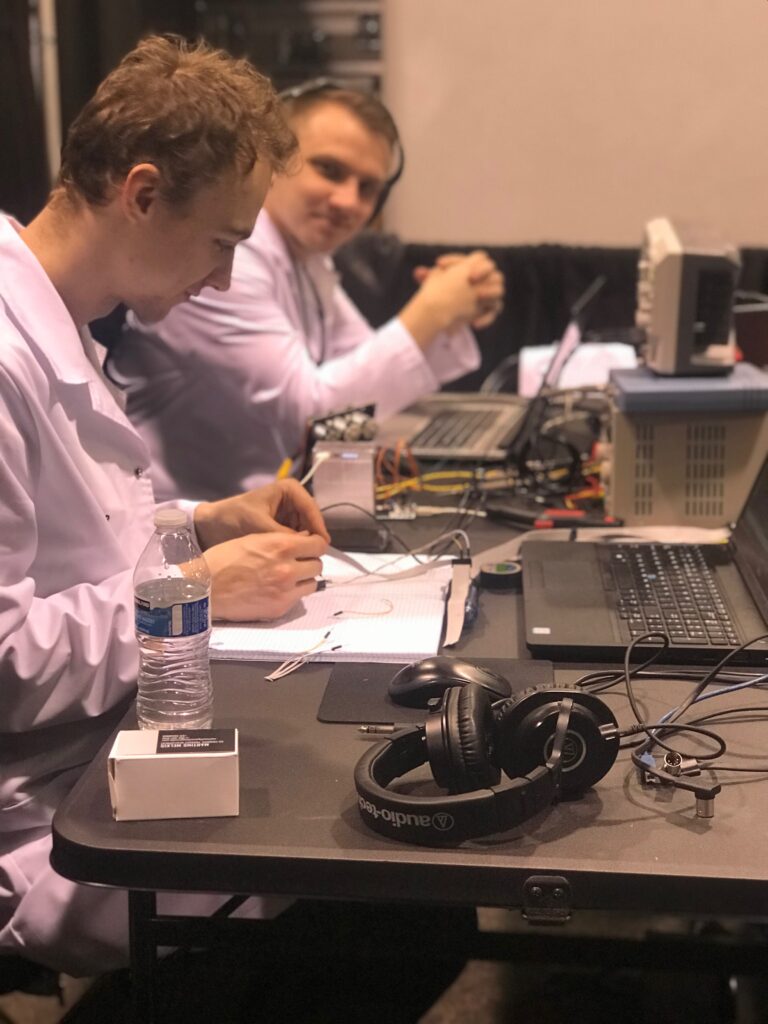

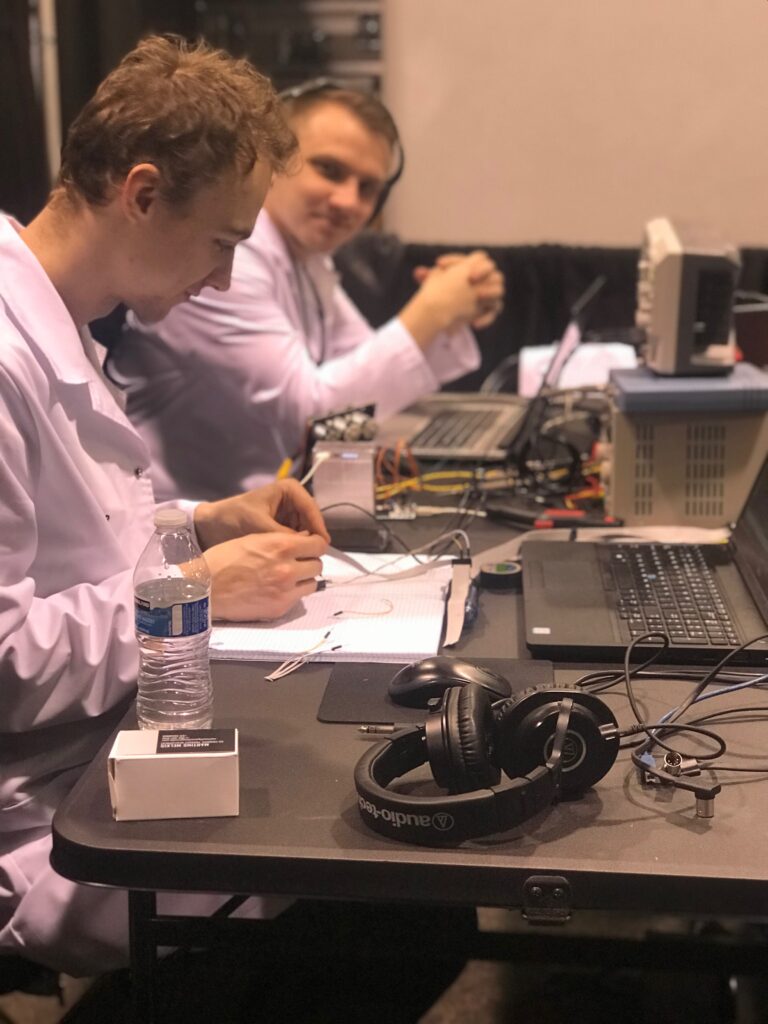

Martiņš, Valters, Kristaps and Vilnis at NAMM

Instead the team decided to buy extra plane tickets for the whole engineering team, and simply continue working on the MOTOR Piano in front of all the visitors.

As a result, the project attracted a lot of media attention and gave our fans an inside look on the development process. The MOTOR Pedal was also briefly featured in the NAMM press coverage.

During NAMM, and also in the following days in LA we showed the MOTOR Piano to many industry friends and fellow engineers and received a lot of valuable input.

Most notably, we spent many hours talking to the MOOG engineering team, and they were kind enough to offer invaluable advice on the synthesizer market and their engineering and product development process.

Thanks to this conversation, we decided to pivot and restructure the whole project and come up with something smaller, less complex and more affordable.

But more on that later!

In 2018, following the release of the first PLASMA Pedal - we were receiving the following type of comment on a regular basis - Wow, guys - I wonder what crazy sh** you will come up with next…

Our mojo was flowing, we were on the hunt for new ideas for creating and manipulating sound, for new ways of combining musical and engineering concepts in order to create a unique musical experience.

One day our head engineer Martins showed up at the office and said he'd had a weird dream about Motors… This statement instantly sparked a long brainstorming session and the matter was settled - we're gonna build something that makes Music with MOTORS.

We started conducting the first series of experiments - placing electromagnetic pickups on various motor types and amplifying the signal, thus producing a variety of gorgeous and nasty drones, resonant noises and screeching tones.

It was clear that the crucial element to creating any Motor-based musical instrument would be an efficient and reliable MOTOR Driver system that could control the MOTOR'S rotation speed (RPM) in real-time with musical precision.

Realizing the challenge ahead, the engineering team recruits Valters, an engineer with a unique set of electromotor related skills and years of experience in this specialized area.

Valters joins the GCA Team and immediately begins work on a proprietary MOTOR Driver microcontroller system that uses Infra-red Optical discs (instead of a Hall-Sensor) in order to precisely measure and control the MOTOR's rotation speed. The first results are promising and we are able to play a Brushless DC MOTOR test-board via MIDI with decent precision.

Valters’ successful Motor Driver experiments set off the green light for the rest of the team to start working on product design.

Two totally different, but equally ambitious concepts are created - the MOTOR Piano and the MOTOR Pedal:

The MOTOR Pedal was designed to incorporate the sounds of brushed electromotors into the world of electric and bass guitar.

The three-motor voice block was capable of tracking a mono input signal and producing a pitched growling motor sound thanks to a specially designed electromagnetic inductor system. The Motors also featured an optical sine wave generator (disc) and controls for Acceleration, Amp Envelope, Blend, Tone, as well as two special FX modes - simple Arpeggiator and Octaver.

The MOTOR Piano is a new type of electromechanical musical instrument.

It is based on a 36 electromotor voice-block (brushless) equipped with specially designed “optical disks” for generating different waveforms. It offers 12-note polyphony with 3 voices (Motors) per musical note, a full-size keyboard with aftertouch, and loads of classic analog synth features including a Low Frequency Stepper Motor that acted as a mechanical LFO.

With only four months to go til' the 2019 NAMM show, the whole team works day and night to turn these crazy instrument designs into working prototypes. The previous years' success of PLUS and PLASMA had set the bar high, and we'd already managed to gain a loyal fan-base that was expecting a new release each year.

Martiņš, Valters, Kristaps and Vilnis at NAMM

However, as the deadline approached it was becoming increasingly clear that we wouldn’t be able to produce finished prototypes in time for the show.

Instead the team decided to buy extra plane tickets for the whole engineering team, and simply continue working on the MOTOR Piano in front of all the visitors.

As a result, the project attracted a lot of media attention and gave our fans an inside look on the development process. The rough prototype of the MOTOR Pedal was briefly featured in the NAMM press coverage.

During NAMM, and also in the following days in LA we showed the MOTOR Piano to many industry friends and fellow engineers and received a lot of valuable input.

Most notably, we spent many hours talking to the MOOG engineering team, and they were kind enough to offer invaluable advice on the synthesizer market and their engineering and product development process. Thanks to this conversation, we decided to pivot and restructure the whole project and come up with something smaller, less complex and more affordable.

But more on that later!

+1 202 657 4587

Gamechanger Audio

Tomsona str 33A

Riga, LV-1013

Latvia